LATEST NEWS

Industry celebrates People In Print and Rising Stars of Print

Over 100 print industry professionals gathered to celebrate this year’s People In Print Awards and Rising Stars of Print Awards at Sorrento in the Park on Maungakiekie One Tree Hill, Auckland. A stormy night did not deter guests from enjoying themselves and giving the awardees ovations as Ruth Cobb, chief executive PrintNZ and New Zealand…

FEATURE ARTICLES

Computaleta can now take you to Arizona and Colorado

Computaleta has signed an agreement with Canon Production Printing Oceania to supply Arizona and Colorado hardware and consumables to the New Zealand market

That was then, this is now

“I have had the absolute privilege of attending every one of these events and the growth of the industry over that time has been nothing short of spectacular,” says Ruth Cobb in her latest column

Inkwise is onshore and onside with New Zealand printers

Privately owned and operated, Inkwise has transformed from a mainly coldset printer into a company that offers one of the country’s most diverse trade print offerings

Tuapeka pushes the boundaries for promotional printed products

A constant drive for innovation backed by a strong team culture and solid business principles have seen Tuapeka grow into the largest supplier of branded promotional products

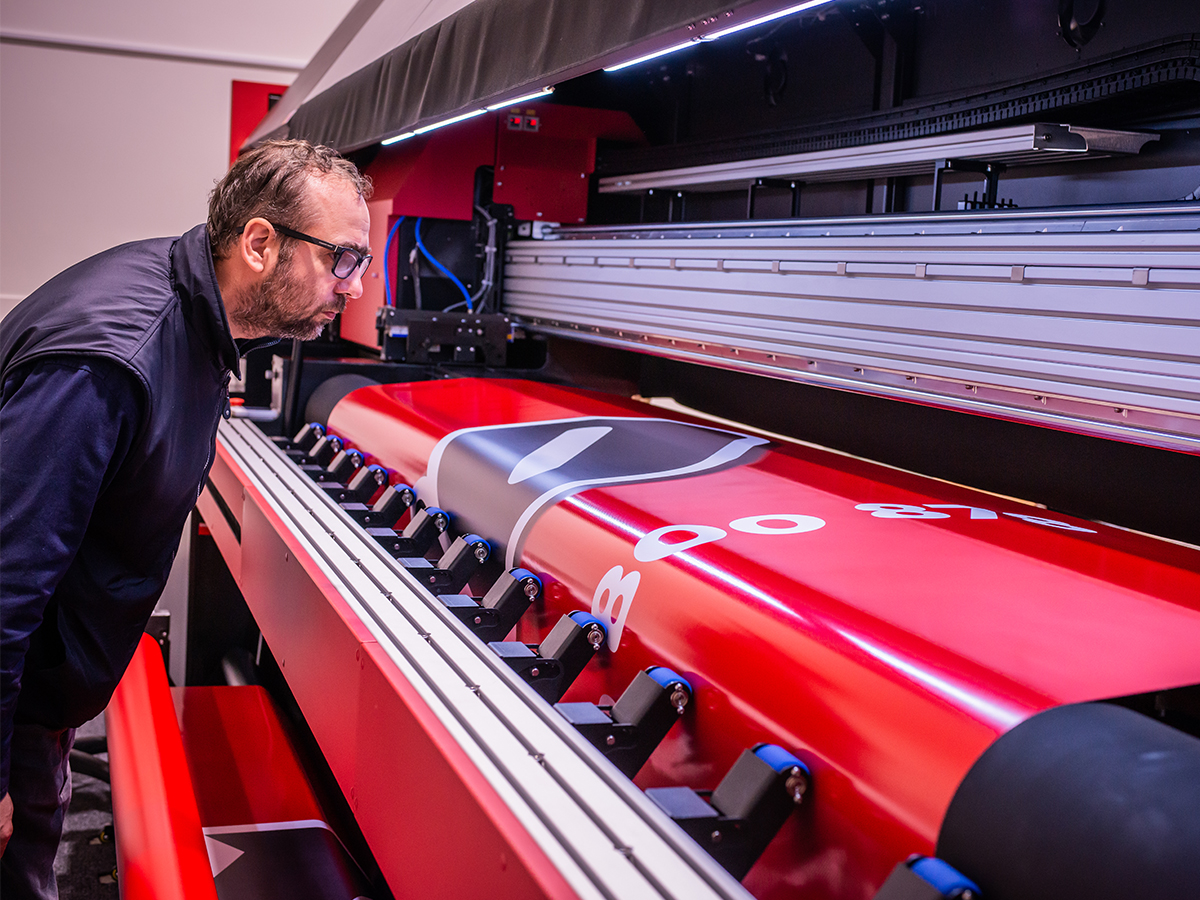

Cactus Imaging installs first Durst 10-channel P5 350 HS D4 hybrid press

The high-speed machine will provide Cactus Imaging with greater efficiencies as well as the opportunity to complete more flatbed work for its clients

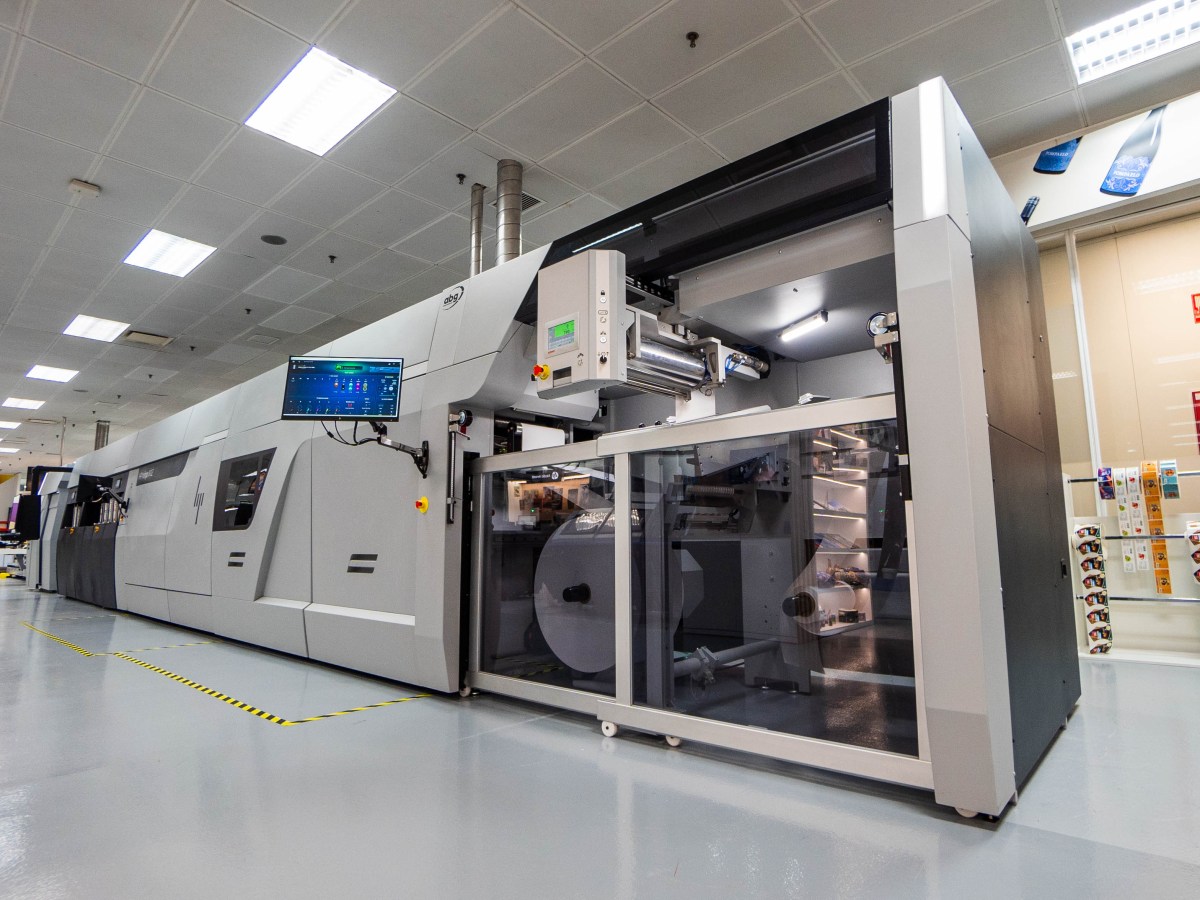

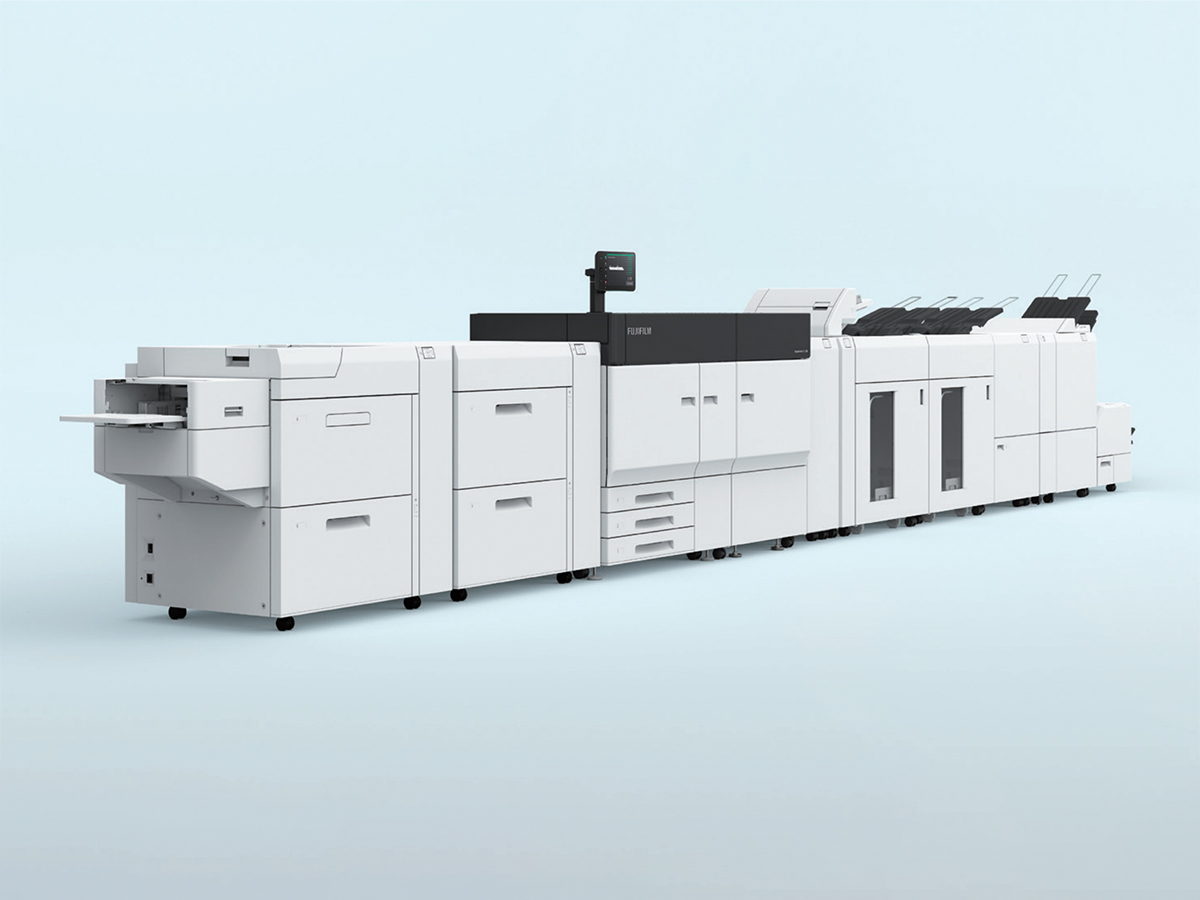

Unimax upgrades to Screen Truepress Jet L350UV SAI S

Jet Technologies and Fujifilm New Zealand partner with Unimax for New Zealand’s first Screen Truepress Jet L350UV SAI S digital label press

LATEST GALLERIES

People In Print & Rising Stars of Print Awards winners

Celebrating the people in our industry, we present the winners who were able to make it along on the…

People In Print Awards and Rising Stars of Print Awards 2024

Over 100 print industry professionals gathered to celebrate the People In Print Awards and Rising Stars of Print Awards…

Annual Total and Spicers Charity Golf Day

Industry golfers had a great day and raised $23,500 for the Prostate Cancer Foundation at the annual Total and…