Screen and Horizon have agreed to develop an AI (artificial intelligence) solution to further enhance Horizon’s Smart Factory.

Currie Group supplies Horizon in New Zealand.

The print and finishing manufacturers aim to release this service to end users in January 2022. They say that the changing nature of the printing industry calls for more diversity, small lot jobs, and short turnaround times. While such demand has seen improvements in efficiency and operating ratios for production processes, unexpected problems can still persist and often become ongoing challenges, hampering efforts to make the most of production efficiency.

Factors that cause these issue include the equipment itself, the operating environment, print data, or operator skill levels. Using changes to settings and conditions can often resolve such problems and improve productivity. However. Screen and Horizon point out that frequently, experienced operators must handle these adjustments. This creates further challenges related to the retirement of experienced employees and requirement to train successors for their positions.

In response to these industry issues, Horizon and Screen have reached an agreement to develop an AI engine that can acquire their combined expertise in digital printing and postpress systems and use it to optimise operations.

Working more efficiently

Peter Scott, managing director for Screen GP Australia and New Zealand, says, “AI is not about replacing skilled workers; it is about maximising their knowledge of processes so that future operators may work more efficiently, reduce waste and deliver faster turn-arounds to customers.

“JDF and CIP3/4 are good but are by no means universal. Horizon is recognised as the world’s leading finishing manufacturer and Screen as the pioneer of inkjet colour web printing. Together with Horizon’s Smart Factory programme, and capably supported locally by Currie Group, the new AI joint development is sure to take printers into future full of confidence.”

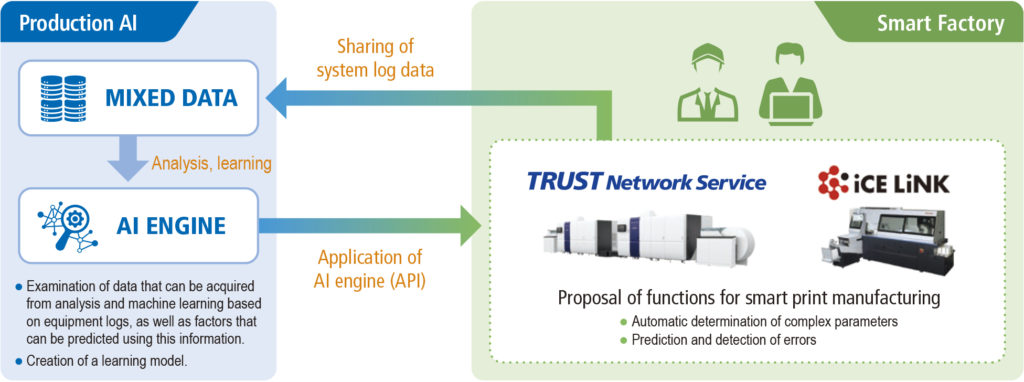

The AI engine will be used to analyse operating data accumulated from different production lines by Horizon’s iCE LiNK and Screen’s TRUST Network Service. The companies says this AI can optimise settings and conditions, identify steps to address potential issues and provide general operational assistance for individual lines. The overall goal of the service will be to support operators and to enable the creation of a production environment that any employee can use easily, safely and efficiently.

Smart Factory transition essential

Alongside their agreement to develop an AI solution, the companies will continue to develop new technologies from the perspective of better integrating the print and postpress processes.

Eijiro Hori, president of Horizon, says, “The transition to Smart Factory will be essential for print and binding facilities of the future. Since the latter half of the 1990s, our company has been leading the way in managing equipment operations using numerical data acquired directly from systems. This new AI-based data analysis project is another step toward the realisation of our goal.

“Statistical analysis of numerical data enables the setup of equipment using a very fine level of adjustment that has so far depended on the experience of operators. It also offers the ability to prevent potential issues before they occur. By effectively utilising AI, I believe we will be able to present a system with the capacity to operate and manage the entire production process from printing to book binding without interruption.”

Takanori Kakita, president of Screen Graphic Solutions says: “Production in the current digital era means people, environment and processes are all interconnected. One company working alone will not achieve the transition to Smart Factory. Among the many areas that must be addressed, one of the most vital is seamless linking of digital print and postpress processes due to its direct connection to productivity.

“By combining the specialised knowledge possessed by both companies, and utilising the power of data and AI, we hope to drive the evolution of production systems. Progress in this field will help to meet various current societal demands. These include those calling for increased diversity in the workplace and the reduction of waste. It will also help to promote the realisation of mass customisation.”