Zünd has expanded its industrial, pallet-to-pallet production portfolio with the new Q-Line with BHS180 Board Handling System and Undercam, featuring intelligent machine control technology and a high level of automation.

The new system has been developed for highly automated, industrial finishing of printed boards for displays and packaging.

According to Zünd, the components, such as the board feeder with Undercam, the new Q-Line cutter and the off-load unit, are optimally coordinated and provide previously unattainable productivity levels.

The new equipment is intended to make it easier for packaging and display manufacturers to automate their cutting operations and achieve maximum efficiency by optimising their production processes and increasing overall productivity.

The Q-Line with BHS180 enables an unsupervised, uninterrupted production workflow and gives users the potential for savings, irrespective of company size. The new machine components generate a speed of up to 2.8 m/s.

The new substructure for Q-Line cutters is made from durable concrete, ensuring smooth operation and optimum cutting precision, even at extremely high speeds.

The beams are made of carbon fibre-reinforced plastic, allowing even demanding materials to be processed at top speeds and the highest quality levels. The machine offers up to 2.1g acceleration thanks to the new linear drive system.

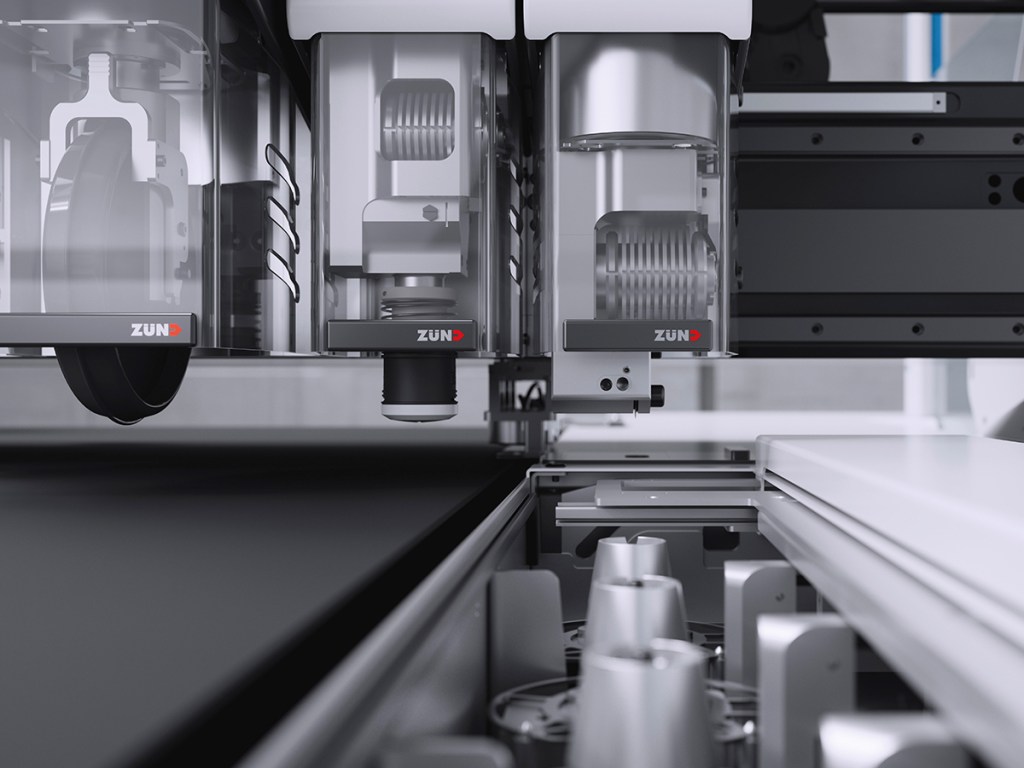

The Q-Line with BHS180 comes equipped with the latest generation of Automo L, providing a creasing pressure of up to 50 kg and can crease with large wheels such as the Creto 150. Automo E excels in the speed at which it lowers and lifts the tools.

Each beam has four modules: two Automo E modules, one Automo L, and one fixed Incam sensor module to capture registration marks, QR codes, and material edges.

The Q-Line with BHS180 removes bottlenecks in digital cutting by eliminating the need for manual material handling. Automatic material transport from pallet to pallet maximises the productivity of the production workflow and prevents idle time.

A customisable, transparent production workflow ensures smooth and reliable order processing by capturing the information stored for each job using QR codes.

The Undercam integrated into the board feeder captures the location of the image printed on the board, identifies any distortions in print, compensates for them, and matches the cut to the print.

During the feeding process, sensors capture the edges of the material, and the board is correctly aligned. If the board is not within tolerance, the feeder grabs it once more and realigns it so it can be fed onto the cutter without interruption.

“The new Q-Line with BHS180 is an all-in-one solution. In addition to the hardware, it also comprises a complete set of services, intuitive and straightforward software, such as the latest Zünd Cut Center – ZCC operating software, Version 4.0, or the Zünd Connect production monitoring and analysing tool, as well as a wide selection of consumables,” said the company in a statement.

“All components were developed with a consistent focus on maximising machine performance and productivity while decreasing setup times. And first and foremost, they have already been extensively and successfully tested by various beta customers, ensuring outstanding results at maximum speeds,” said Zünd.

The new Q-Line with BHS180 is available as a dual-beam system in three different sizes: the Zünd Cutter Q 32-32 D with a working width of 3.2 m, the Q 22-32 D with a working width of 2.2 m, and the Q 18-32 D with a working width of 1.8 m.

Zünd equipment is sold and supported in New Zealand by Starleaton.