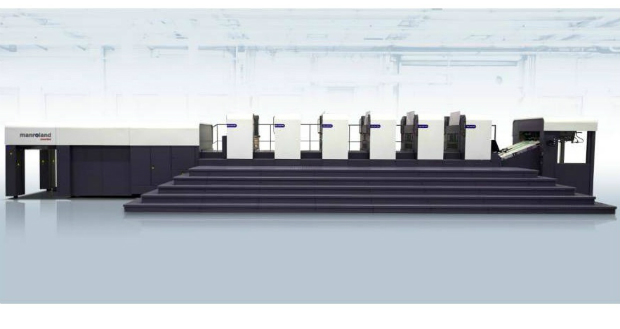

Manroland Sheetfed has unveiled its new flagship Roland 700 Evolution printer in Germany, the first full update for the series in four years.

The Evolution will supersede both the Roland 700 HS and 700 Direct Drive offset machines, which it launched back in 2010. Manroland says the quality it produces is ‘hitherto unseen’ in offset printing.

Rafael, Penuela, chief executive of Manroland Sheetfed, says, “Throughout our company’s history we have been known for bringing innovative new technology to the printing industry. “The Roland 700 Evolution is the latest ground-breaking new press which we believe will be yet another milestone in the evolution of print technology.”

Designed from the ground up, Manroland says the machine includes nine new technological developments aimed at improving efficiency, productivity, operation and quality, while saving on production costs. A new central console replaces buttons with touchscreen panels, giving graphic information for better flexibility and comfort for the operator. A new feeder pile transport aims for productivity and improved sheet travel from the feeder to delivery with fewer interruptions, less start-up waste and less walking distance to the feeder.

The company has solidly fixed the suction head to reduce vibration and wear while ensuring safer sheet separation and higher average printer speeds. The press also has completely redesigned cylinder-roller bearings, with separate bearings for radial and axial rotation for longer life and better print quality. New dampening units bring greater solidity and lessen vibrations during passing of the plate cylinder channel, meaning fewer stripes as well.

Gerhard Aichhorn, managing director of Samson Druck GmbH (l) purchased the first Roland 700 Evolution, with Rafael Penuela, CEO of Manroland Sheetfed GmbH

Software for practice-oriented roller washing cycles reduces downtime and makes for a more precise dosage of the dampening solution across the entire width, reducing the possibility of skewing the dampening dosage roller.

A three-phase AC motor makes for lower energy consumption with higher power output. Manroland says the machine has no need for wearing parts, carbon brushes or additional costs for part, helping it to further cut down on unproductive time, strengthen the market position of printers and raise its green credentials.

The Evolution also features a new chambered doctor blade system, which the company says will exceed expectations in the gloss effects it can produce. The system, with additional profile, aims to provide higher solidity over the width of the doctor blade, and a more even varnish application.

Manroland says that not only does it feature better absorption of vibrations from the Anilox roller and doctor blade caused by passing the coating form cylinder, it also results in fewer stripes, especially in combination with pigmented varnish.

New suction belt sheet brake technology offers higher printing speeds, with improved sheet alignment and tail edge stabilisation. This gives a more even pile contour and reduces the risk of misaligned sheets in the delivery pile.

More than 400 guests from around the globe attended the Evolution launch

More than 400 guests from around the globe attended the Evolution launch

Stefan Finger, head of R&D with Manroland Sheetfed, says advance orders have been flooding in with ‘several’ customers signing up during the trial stage.

He says, “We observed the challenges faced by the market, we listened to our customers and we learnt from the daily experiences of our own printers in our Print Technology Centre.

“Our preliminary demonstration and trials of the new press to the first customers were encouraging and we knew we were on the right track.

“The number of customers registering for the launch event has exceeded our expectations; the demand was such that we have now included an additional day with some more dates in the new year.”

Austrian printing and packaging outfit Samson Druck will be the first to install the Evolution at its Salzburg site.