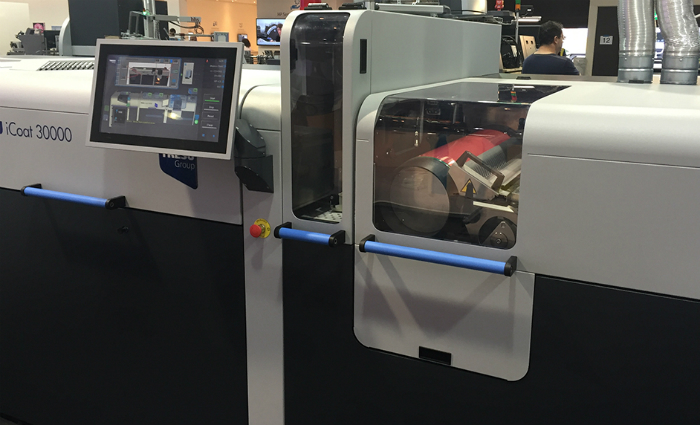

Interpack starts this week and among the technology on offer, Tresu will demonstrate its new flexo coater for applying varnishes to digitally printed folding cartons and synthetic materials.

The HP Indigo 30000 is supplied in New Zealand by Currie Group.

The coater will work in line with an HP Indigo 30000 digital press. Kim Krintel, vice-president for Tresu Digital Solutions, says, “Coating is a vital post-print stage in the digital packaging printing process, ensuring the finished product is both resistant and aesthetically appealing.

“The Tresu iCoat coater integrates perfectly with the HP Indigo digital press, applying full and spot varnishes in perfect register with minimal makeready time, and the result is a high-speed single-pass line with minimised waste or logistics. Its efficiency means converters can efficiently offer a host of added-value short-run or variable-data solutions that reduce supply chain costs, including targeted promotions, multi-versioning, package designs, serialised data, and samples on-demand.”

Like the HP Indigo 30000 digital press, Tresu iCoat has a maximum speed of up to 4600 sheets per hour, or 3450sph in four colours, handling substrates of maximum format 750mm x 550mm in paperboard and metallised boards between 250µm and 600µm. It also accommodates PVC and polypropylene substrates up to 630µm, and PET substrates up to 400µm.

The coater also comes with quick-change sleeve technology and automatic chamber cleaning, enabling varnish change-overs within minutes. Tresu says the coater’s sleeves assure smooth production without mis-registration at maximum speeds equivalent to that of the HP Indigo 30000 digital press.

Applications include food, beverage, pharmaceuticals, personal care and industrial products.

The company also provides consumable products and equipment including coating media and tapes, coating circulators, sleeve cutters, as well as also twin-unit and inkjet coating machines.