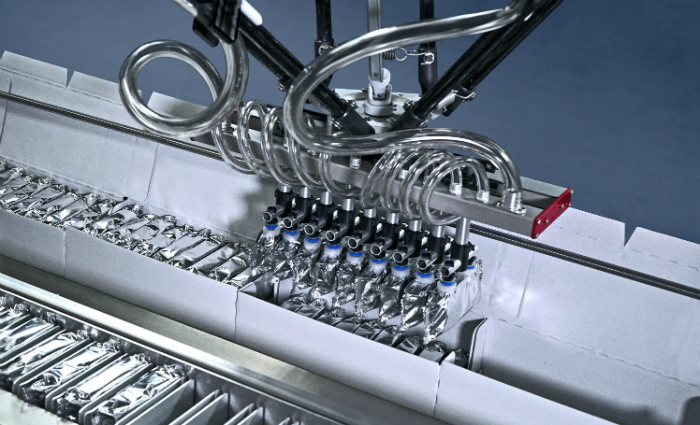

Bosch Packaging Technology has unveiled its new Presto D3 machine range, an upgraded robotic platform for picking, placing and collating a range of wrapped products.

Marc de Vries, sales director of the robotic portfolio at Bosch Packaging Technology, says, “The new jam-prevention feature on our proven Presto platform is designed to improve the ease of machine operation and at the same time, increase the uptime and efficiency of this type of machine. With this customer-focused technology, we underline our commitment to helping enhance their efficiencies and reducing their TCO.”

Bosch developed the Presto D3 machine range in several configurations to make it adaptable to different factory and production layouts. The solution offers one or two infeed conveyors and allows for multiple product and carton types and sizes on the same machine, like single, dual or twin collators with options for left, centre and right-hand entries. Using the latest human machine interface and Gemini 4.0 controller, operators can design simulations of new formats without actual products.

The Presto D3 collator uses an air blow ejection system that rejects products which are out of specification. A new automatic unjamming device actively controls product jams, while the machine continues to run at full speed.

All D3 robotic solutions integrate Bosch and third-party primary or secondary packaging machines. Bosch says the new portfolio offers flexible and scalable robotic solutions that allow customers to adjust quickly to current production needs and to reach future manufacturing goals.