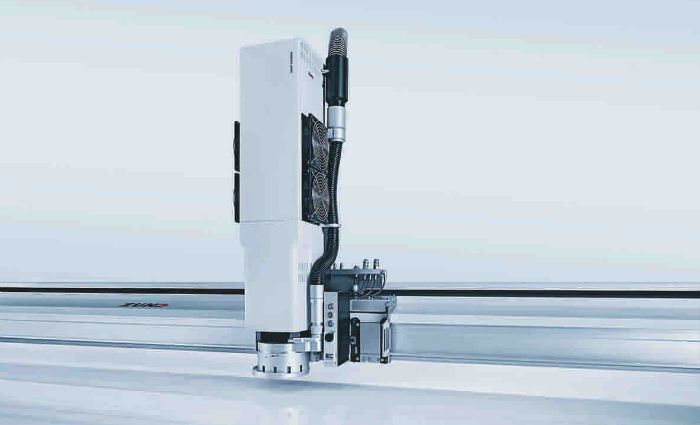

Wide format cutting table manufacturer Zünd has announced a laser module for sign & display applications: the LM 100W laser module.

The new system will cut polyester fabrics and seal the edges at the same time. Zünd says that the LM 100W laser module prevents frayed edges on the substrate and automates a separate, manual operation, eliminating the need for seaming. The company claims the LM 100W delivers impeccable cut quality and flawless repeatability. As a touch free process, laser cutting doesn’t require hold-down during processing.

The Zünd laser module uses an air-cooled CO2 100W laser with a processing speed of 44mpm. The Class 1 laser requires no special safety gear such as protective glasses. The laser module is fully enclosed, which provides reliable protection for the operator, according to Zünd.

The company says it takes one operator a few simple steps and a matter of minutes to convert a Zünd cutter to a full-blown laser-cutting system. Once the operator completes the laser job, reconfiguring the cutter for the next application presents no problem.

Zünd says soft signage offers tremendous potential in the vast and diverse world of visual communication media. The company adds that, as polyester fabrics take over applications previously ruled by paper and PVC substrates, its new cutter will become a necessity.