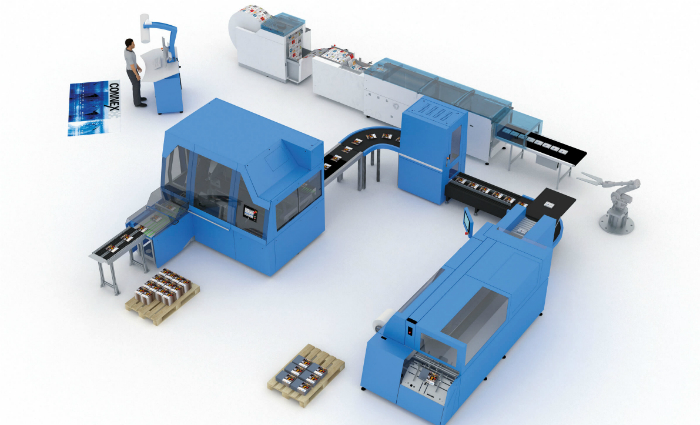

At the upcoming Hunkeler Innovationdays, finishing manufacturer Muller Martini will showcase its Finishing 4.0 philosophy in a compact form with three solutions for producers of digitally printed books and magazines in runs right down to one copy.

In addition to the Vareo perfect binder, as a world premiere, the company will show Hunkeler’s roll-to-stack line connected to Muller Martini’s Connex data and process management system at an inline production line for softcover books. So functions, such as automatic digital page assembly, the JDF interface, job management, control of the printing press, and production tracking via JMF will be available for combined Hunkeler/Muller Martini solutions in the future.

It will be the first time Muller Martini will enable the data and process management system, which until now has been used exclusively for its own systems, to be used with the systems of another machine manufacturer. It will suit companies producing softcover books using a combined Hunkeler/Muller Martini solution in runs right down to one copy.

The company has outlined the process belowm which it will demonstrate live using school textbooks:

Connex imposes the PDF data for the Hunkeler line and transfers them to the respective printing systems.

Pre-printed rolls are unwound using the Hunkeler components.

The paper web is then split and merged along the paper grain direction to result in a double-layer paper web. Dynamic Hunkeler cross cutting on the fly (“Dyna Cut”) enables variable trim lengths.

The paper is then stacked by Hunkeler into book blocks, with variable spine length, variable page counts and variable content (VDP). The book blocks are transferred to the Vareo using Hunkeler’s newly developed transfer station.

Muller Martini will also demonstrate automatic book block feeding with variable spine lengths for the first time. At the end, the VDP school textbooks are transferred from the Vareo to the fully variable-size InfiniTrim three-knife trimmer, whose innovative trim concept wowed visitors at drupa 2016. All the components are controlled and monitored via Connex.

In the saddle stitching segment, Muller Martini will produce a roll-fed product (personalised coloring books for children and adults) and two sheet-fed jobs (a personalised hybrid catalogue consisting of offset and digital signatures and a guide to the city of Lucerne). Connex will perform job handling, including digital page assembly.

It will give a demonstration at the Presto II Digital saddle stitching system, equipped with variable-thickness stitching heads, shown with an unwinding system, cross cutting system (both from Hunkeler), a flat pile feeder and a folding machine (from Heidelberg) – using fully variable roll-fed and sheet-fed products of how all the required production parameters and cover matching are controlled touchlessly on a barcode basis. The stitching machine and three-knife trimmer are set fully variably and the thickness can vary from product to product.

Muller Martini will also present new connectivity options (Connex has new standard interfaces with Heidelberg’s Prinect, the HP SmartStream Production Center and Enfocus Switch), a new surface (making it even easier for users to create or edit new jobs) and the new Connex.Info 4.0.

Muller Martini adds Hunkeler