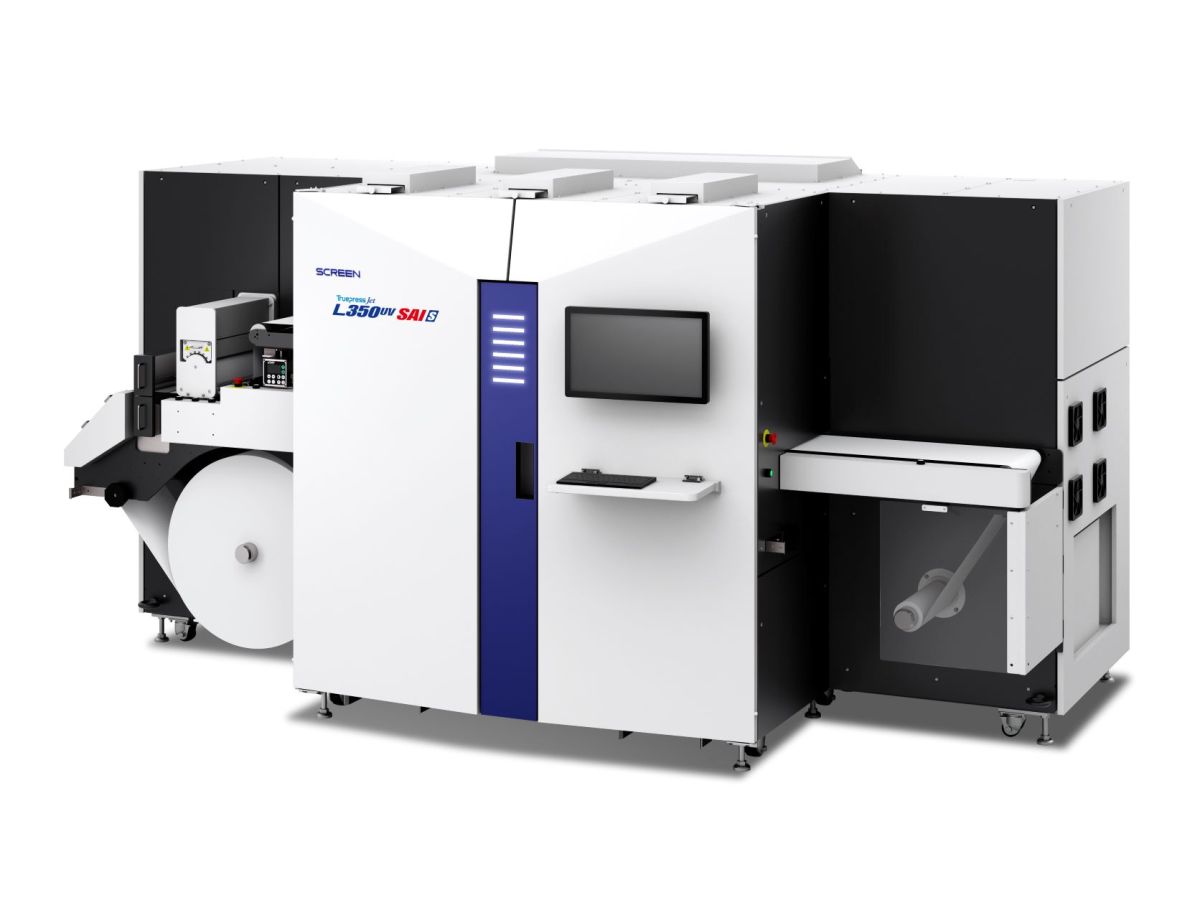

Screen GP has introduced a new high opacity white mode for the Truepress Jet L350UV SAI S inkjet label printing system.

The high-opacity white mode is available as a retro-fit to existing Screen Truepress Jet L350 SAI installations, or as an inclusion in new installations.

Screen says white ink is most commonly applied as a base layer on coloured, metallic, or clear stocks. In these applications, white ink is printed first, followed by cyan, magenta, yellow, and black (and special colour) inks on top. In these instances, the white ink is used to overcome the colour, or translucency, of the substrate, providing a white background or base. On clear substrates and clear bottles, white is necessary to prevent light from passing through and washing out and affecting other colours.

The company adds that, as digital has permeated the label sector, both the volume and value of digital printing shipments in the label printing market have shown consistent annual increases. The growth rate of digitally printed labels has been particularly strong, when compared to shipment volumes, demonstrating the high added-value offered by digital printing.

In addition, special interest in labels reflects consumers’ desires to buy specific products, including those promoting local production for local consumption and limited time campaigns, as well as original designs that may involve variable content.

Prime labels

Screen says these trends have in turn led to a growing number of situations in which high quality items such as ‘prime labels’ are required. However, if a bottle or package’s contents, for example, are darkly coloured, the colour may show through a label, affecting the impact of its design. This has become a point of concern for printing companies seeking higher quality where fundamentally translucent media is concerned, according to Screen.

In response, Screen has launched the high opacity white mode as an option for its Truepress Jet L350UV SAI S digital label press. Screen says that, when used with clear film or similar labels, this new printing mode provides more opaque white, preventing the colour of bottles or package contents, from showing through. It adds that this helps to maintain rich colour saturation, ensuring high-quality labels with eye-catching visual appeal, even when applied to translucent base materials.

Screen says the liquor, cosmetics and toiletry industries increasingly employ UV inkjet-based digital printing as a substitute for silk-screen printing. Digital printing provides these industries with a number of advantages, including shorter turnaround times, lower costs and reduced environmental impact, and demand is expected to grow consistently going forward.

Screen has a history of developing inkjet printing technologies. Also, it has also worked to promote production line automation and create a range of solutions to resolve specific customer needs. In combining these various aspects, Screen hopes to open up further new markets and contribute to the continuing growth of the overall label printing industry.