Heidelberg has introduced neon pink to its Versafire digital printing range, the second neon colour after it introduced neon yellow late last year.

The neon pink toner will be available towards the end of the year.

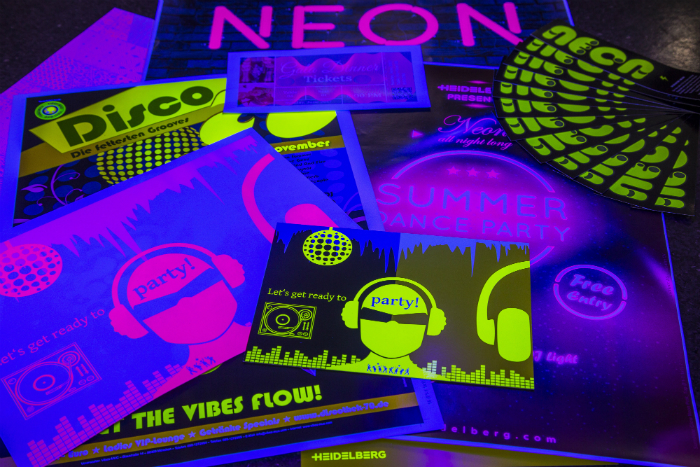

Heidelberg says Versafire CV owners are able to deliver even brighter posters, party invitations and bills, advertising leaflets, even in short runs, with or without personalisation, and most important in a most cost-effective way. The neon toner glows under UV light, enabling it to attract even more attention and add unexpected touches to printing applications in the digital printing field.

Stephan Plenz, member of the Heidelberg management board responsible for digital technology says, “Having more than 1500 Versafire systems installed in the graphic arts market is an impressive landmark, demonstrating the successful interplay of digital and offset technology for the benefit of our customers. The customer feedback switching from various vendors towards Heidelberg’s Versafire in terms of easy installation, error free operation, availability, price performance ratio and simple workflow integration is just overwhelming. Based on this it is just a logical step to further develop and integrate the Versafire digital printing family.”

In total, four additional toners can be used each in addition to CYMK: high-opacity white, varnish for full-area or spot coating, neon yellow and neon pink. The operator can realise the applications quickly and confidently, with using the new Prinect Digital Frontend Version 2018 features or using the PDF-Toolbox.

Versafire is the cut sheet toner based digital printing system from Ricoh that Heidelberg markets.

All hardware required is the toner and an additional developer unit. Beside the low investment costs of the new toner, it can also be retrofitted to all Heidelberg Linoprint CV or Versafire CV printing systems with five colour configuration. Another proof of the high level of investment security Heidelberg is offering.

A feature of the Versafire product family is the ability to print on a wide range of media. However, settings for heat-resistant plastics or structured materials may be quite complex. To enable every Versafire user to print outstanding results, Heidelberg offers a new training program which includes an innovative and exclusive Media Management Tool for the Prinect DFE, to quickly setup, save and recall all media settings for complex substrates. In other words: Once a new substrate is set up by the operator, the corresponding settings can be saved and recalled anytime. Even more, the settings can be exchanged between Versafire machines. This enables Versafire users to broaden their range of printing substrates, realizing a minimum on make-ready time and to stay ahead of competition.”