Graph-Pak has announced it will expand its porfolio further, bringing Swiss manufactured PBT photobook finishing solutions to Australia and New Zealand.

Tom Raph, managing director of Graph-Pak, believes the range will enable digital printers to produce finished photobooks easily and cost effectively. He says, “The are few areas of print that are as lucrative as photobooks and other digitally printed books. The equipment we are now supplying from PBT means any digital print business can now enter this rapidly growing sector without the high capital outlay of traditional hard cover manufacturing lines.”

He adds that the PBT solutions, built to produce hard cover photo books and and square back hard cover books in small quantities, offer ease of operation, a high degree of automation, short make ready, and high quality output with minimum spoilage. He says, “The PBT equipment range fills the gap between semi-automatic, manual operated equipment, and industrial machinery, designed for high volume book production. It will mean that digital print businesses have the ability to produce finished books in house.”

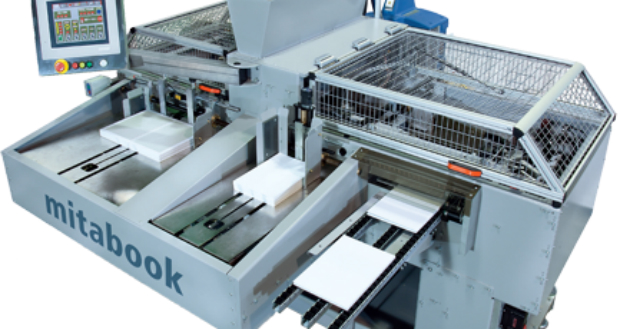

The equipment range includes the Mitabook automatic hard cover casing-in line. According to Ralph, it differs in its function from other machines as the operation does not require the usual wing; book block and case are combined with hotmelt instead of PVA cold glue. This technology also permits to immediately case in after trimming PUR bound book blocks without intermediate storage for curing.

Taking up 2 x 2.5m floor space, the machine requires one person for opperation. Ralph says that all product data input in touch screen terminal and automatic size change takes seconds. An additional hotmelt line in the fold area adds strength to the finished book and the enclosed glue system saves costly clean up at shirt end. Since PBT launched the system, the Mitabook has been installed in 38 digital print businesses.

Graph-Pak will also supply the Mitacase automatic casemaker, first shown at drupa 2012 and now manufactured in series. Ralph says, “With the development of this technology, the same requirements for the short run market have been taken into account like the Mitabook. Quality cases, short make ready and simple operation with one person are the main characteristics of the creasing and folding machine.

“Prior to producing a layflat book block on the Mitamax, the individual sections need to be perfectly creased and tightly folded. The Mitafold, using special creasing tools enables clean folding of even most difficult papers like silver halide and coated papers, regardless of grain direction.”

He describes the Mitamax section gluing machine as, “simple and reliable technology that produces valuable and attractive lay-flat book blocks.”

It can generate a book block showing panorama images without interruption in the fold area by full back to back surface gluing of folded, one side printed sheets. Ralph says, “This type of producing a book block is not only used in the photo book industry, but is attractive to the advertising industry to design company profiles, catalogues for cars, furniture and architectural projects.”

PBT has, in development, a lay-flat book block production line named Mitablock. This machine will manufacture in-line flay-flat book blocks starting from a flat sheet. It will use Hotmelt to glue folded sections back to back and have an extended size range up to 400 x 450 mm. The company will make Mitablock available later this year.