Aarque Group has made a strategic investment in the cutting-edge and highly efficient Felder Group Format 4 kappa classic horizontal beam saw for its Auckland office. This move aims to enhance cutting capacity and meet the growing demand from customers.

Aarque Group’s choice of Felder Group machines, sourced through local supplier Jacks, is driven by the brand’s exceptional reputation, which has consistently met the highest standards of professional users for over two decades.

The manufacturer is renowned for delivering customized, high-performance solutions that incorporate innovation, maximum operating comfort and unrivalled productivity.

The Felder Group Format 4 beam saw kappa automatic classic represents a significant advancement in machinery, specifically designed to streamline the cutting process in workshops and manufacturing facilities. With its state-of-the-art features and precision engineering, this beam saw ensures outstanding performance and accuracy.

Among the standout features of the Format 4 beam saw kappa automatic classic is its impressive automation capabilities. Equipped with advanced software and a user-friendly interface, this machine enables efficient and precise cutting operations.

The automated control system allows users to input cutting specifications, including dimensions and angles, while the machine takes care of the rest.

By eliminating the need for manual adjustments and measurements, this automation greatly reduces the margin for error and increases productivity.

The kappa automatic classic boasts a robust construction and a powerful cutting unit, guaranteeing durability and consistent performance, even under heavy workloads.

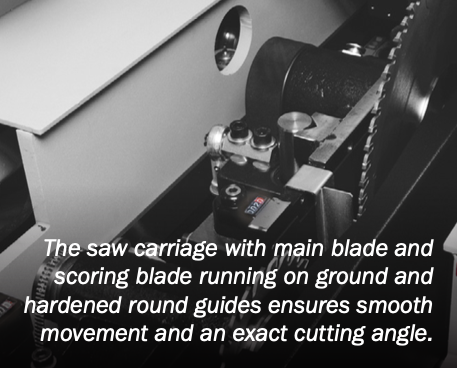

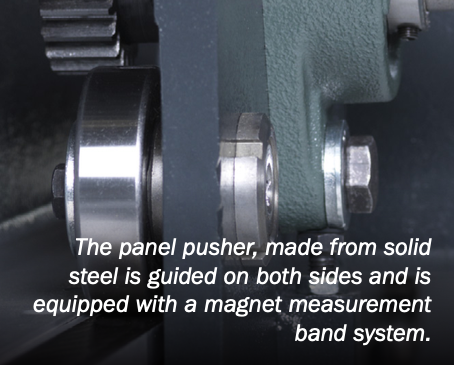

Its sturdy beam and high-quality sliding table provide stability and smooth operation, facilitating the effortless movement of workpieces during cutting. Moreover, the machine’s precision- guided saw carriage ensures accurate cuts, minimizing material waste and optimizing production efficiency.

Additionally, the Format 4 beam saw kappa automatic classic incorporates advanced safety features to protect operators during operation. Blade guards, emergency stop buttons, and sensors contribute to a secure working environment, reducing the risk of accidents.

Aarque’s classic model provides cutting lengths of 3.2 metres, two movable support tables with an air cushion function, and a pressure device for precise right-angle cuts during crosscutting.

To achieve perfect, chip-free results, the main saw aggregate is equipped with a 7.5kW motor, a 320mm saw blade diameter, and a 68mm saw blade projection.

Steve Wilton-Jones, Aarque Group’s national equipment sales consultant, expressed his satisfaction with the new Felder Group pressure beam kappa automatic saw, which replaced an older model of a wall saw previously used.

“The upgraded equipment allows Aarque Group to offer faster turnaround times and improved cutting quality,” said Steve Wilton-Jones. “The highly automated and electronically controlled cutting technology contributes to smoother cut finishes and enhanced accuracy.

“Moreover, the Format 4 beam saw expands Aarque Group’s capabilities by enabling the processing of a wider variety of materials, including PVC, corflute, ACM, and even our steel composite display panels. It also facilitates quick and efficient multiple cuts of various sizes to meet the needs of their customers.”