The world’s biggest label printing show Labelexpo Brussels is into its final day today, with label printers looking at the latest developments that show an industry embracing the digital age, and embracing partnerships between developers.

Evidence of the move from analogue to digital is provided by the biggest stand at the show, HP Indigo, supplied here by Currie Group, with its 2,400sqm stand hosting the largest portfolio of labels and packaging presses in the industry.

HP Indigo is showcasing what it says is its market-transforming Gem technology, enabling the application of fully digital graphic embellishments in one pass. Developed with JetFX, Gem will enable streamlined production of digital spot and tactile varnishes, special effects, digital foils, and more.

Also in the showcase is the HP Indigo 8000 Digital Press, the industry’s most productive narrow-web press, which is demonstrating new levels of speed and capacity for mainstream production, and there is the newest of the best-selling HP Indigo WS6000 series. In addition the HP Indigo 20000 Digital Press, with its mid-web format capturing new opportunities for digital flexible packaging, labels and sleeve applications, is in action at the HP stand.

Xeikon is expanding its UV inkjet portfolio with its new PX2000 UV inkjet digital label press, an entry level machine, available in a 4-colour and 5-colour configuration. All presses within the Panther Series are powered by Xeikon’s Panther technology, using PantherCure UV inks and take advantage of the Xeikon X-800 digital front-end.

Filip Weymans, VP Global Marketing, Xeikon says, “We are excited to be expanding our UV inkjet line of digital label presses so quickly. This rapid product development underscores our commitment to offering a broad portfolio of complementary solutions, for both our Cheetah Series of dry toner and Panther Series of UV inkjet digital label presses.

The entry-level Xeikon PX2000 has a web width of 220mm, running at print speed of up to 50m/min, which Xeikon says makes it the ultimate in productivity and throughput on the most optimal web width. These Panther presses will be available in two colour configurations, with the 4-colour press field upgradable to a 5-color configuration to allow label converters to add white ink.

A new name at the show is Mouvent – a joint venture from Bobst and Radex, focused on digital printing – has revealed three digital label printers, which can all print up to seven colours on a variety on substrates – paper, self-adhesive and wet-glue labelstock and flexible materials – at production speeds of up to 100 m/min with a native resolution of 1200×1200 and optical 2000dpi.

The new printers include the LB701-UV mini label press, the LB702-UV label press, which Bobst says is the most productive digital label press in the narrow web segment, and the LB702-WB label press, which uses only 100% water-based Mouven Inks, making it 100 per cent free of VOCs (volatile organic compounds) and 100 per cent food safe.

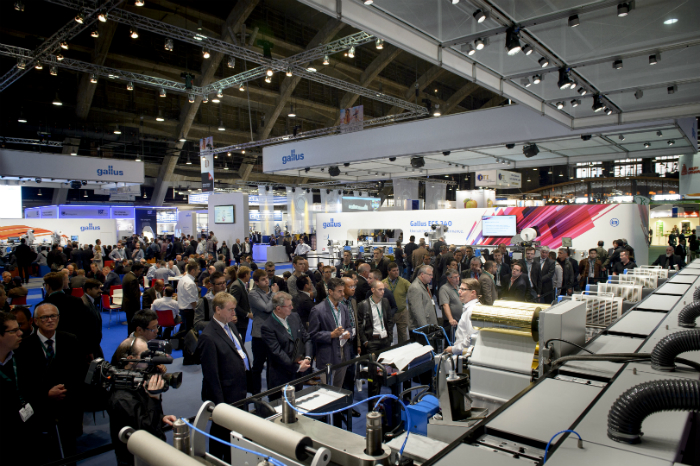

Gallus is focusing on reduced throughput times for manufacturing digitally printed labels by showcasing the Gallus Labelfire digital label printing press with added inline finishing processes.

On the basis of numerous customer requests, these functions have now been expanded to include the rotative screen printing unit. The fully integrated screen printing unit can be positioned upstream or downstream of the press. In front of the digital printing unit, for example, Gallus says the printer benefits from the unbeatable opacity of white screen printing ink. Downstream, the entire pallet of advantages of screen printing can be applied, such as the haptic effects of spot varnishing or safety applications with special screen printing inks.

In contrast to existing digital label printing presses on the market, which only print digitally and then perform further processing steps for the label in a downstream process, the Gallus Labelfire can produce finished and die-cut labels in a single production operation. Gallus Labelfire achieves faster production times for digitally printed finished labels and wastes less paper. This saves label printers time, costs and material compared to a multi-step production process, as there is no changeover required for subsequent further processing. Additionally, thanks to the latest-generation inkjet printing heads from Fujifilm, the Gallus Labelfire achieves a native resolution of 1200 dpi, which is comparable to offset printing quality.

Labelexpo is not all digital though, Gallus is launching n the new platform system, the Gallus Labelmaster Advanced line, which it says is the fastest plabel pres sit ahs ever produced, can virtually meet any requirement and be configured to include as much or as little automation as necessary. By offering this modular system, Gallus says it is ensuring that label printers can satisfy prevailing market requirements and always remain fit for the future – all for a level of investment that it says would previously have been inconceivable for premium products.

The new Gallus Labelmaster machine platform boasts a whole series of product highlights, such as an extremely short web path of just 1.4 m between printing units and a high maximum speed of 200 m/min. The lightweight aluminium printing cylinders that were specially developed for this machine type can be changed in just a few quick steps, thus ensuring that job changes can be completed with unparalleled speed.

All the major names are at the show, more reports to follow.