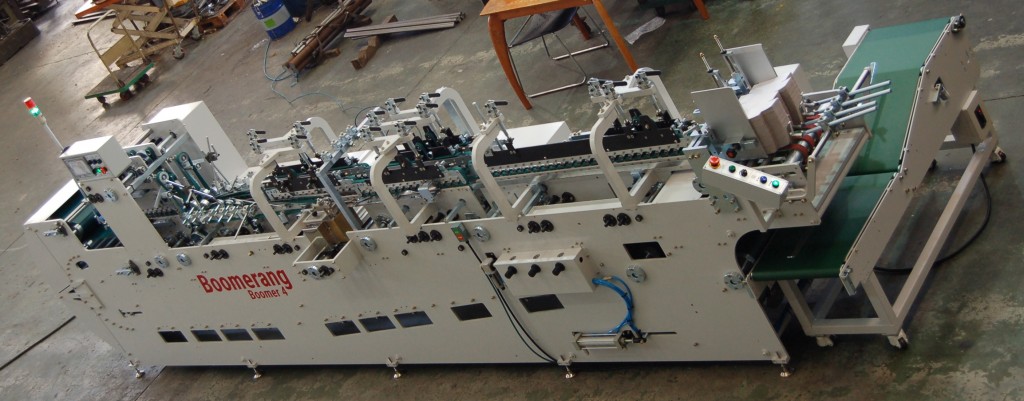

Machinery supplier APM says it has found a gap that needs filling in the local packaging machinery market: the Hatten Boomer 4 returning folding box gluer.

The Boomer 4 saves on time and boasts a small footprint

Alex Peters, managing director at APM, believes the Hatten Boomer 4 (short for Boomerang) returning folding box gluer stands out for its appeal to a range of packaging and print packaging companies. He says, “We see companies operating in a quite complex and competitive business environment so anything they can do to develop an edge must help them. This machine will specifically benefit companies that are doing folding cartons plus on time print finishers. “The Boomer 4 is aimed at increasing your productivity. It will appeal to companies wanting higher productivity from its quick job change-over combined with easy and simple maintenance. This machine will give a fast return on investment. He says that the machine needs one operator instead of two or three because the machine returns on itself back to where the operator is running the die cut blanks. He says, “A single operator can run the machine and collect the folded glued products at the feeder end of the machine. A single operator can run 18000-20000 sheets an hour. At 5.8m long, the machine boasts a small footprint for a folding carton gluer. Peters says, “Normally it would double on itself to about 10-11 metres so then you an operator at the start and the end. That’s the beauty of the return operation. “We have done business with Hatten for 20 years and we have sold some of their other gear. Their big die cutters are quality equipment. We know Hatten and it has good product.â€