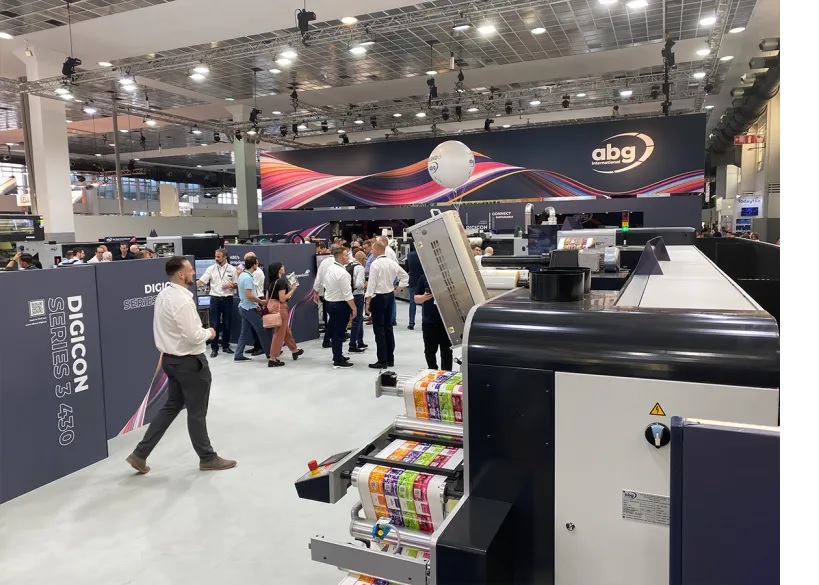

A B Graphic International (ABG) showed its biggest presence yet at this year’s Labelexpo. The company unveiled its automation technology and showcased 13 finishing machines.

Currie Group supplies ABG in New Zealand.

ABG also showcased its latest product innovations, including advancements in non-stop winding technology and the new turret rewinder model.

A few days after celebrating the milestone of 2,500 sold units of its Vectra turret rewinder, ABG formally introduced the next generation of highly automated machines. It has made these models available in hot melt glue (Vectra G) and glueless (Vectra) variants.

Visitors saw Converter, a new fully modular converting line with higher speeds, new flexo technology and a smaller footprint.

Other products on show included a Digicon with screen and Ecoleaf unit for sustainable foiling; DigiLase 4.0; DigiJet 330; DigiLite; SRI3 430 with monochrome inkjet; shrink sleeve seaming; doctoring solutions; and an entry-level SRI.

ABG’s stand also featured a booklet module and its partner Maan Engineering’s module for laminate and linerless label solutions.

To complete its presence at the show, ABG collaborated with HP to demonstrate its non-stop unwind and rewind system. It integrates into the V12 production line as a single platform. Guarding measures ensure operator safety, ease and comfort during operation. It can reach speeds of up to 120 metres per minute. In terms of performance, it delivers what ABG calls “the best tension control’, making it highly reliable for various applications.

Matt Burton, global sales director for ABG, says “Key to ABG’s leadership in the print finishing market is our ability to create solutions for the market as the market evolves. With the addition of ABG’s non-stop winding technology, label printers can maximise the potential of the HP Indigo V12 Digital Press.”