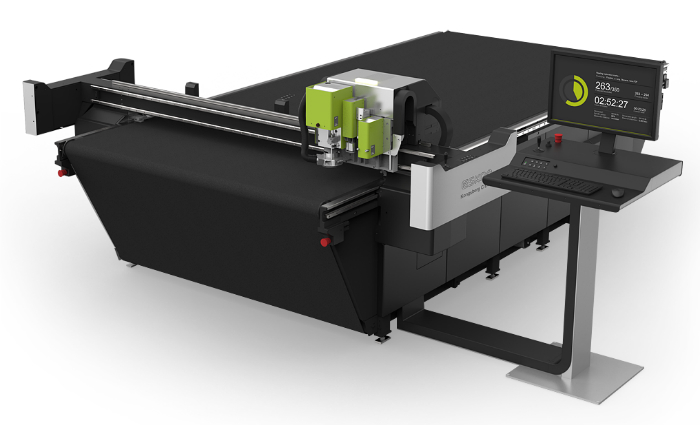

Fujifilm Business Innovation has announced the release of the Esko Kongsberg C Edge digital cutting table, which offers an upgradeable table design.

The company says Esko has designed this latest solution, in the Kongsberg C multifunction digital finishing series, specifically for signage and corrugated packaging converters. Fujifilm Business Innovation supplies Kongsberg cutting tables and ArtiosCAD software and Studio software in New Zealand.

Grant Blockley, application and packaging specialist at Fujifilm Business Innovation, says the new table has a completely upgradable table design that avoids costly reinvestment for customers as their business grows. He says, “The new C Edge is designed to grow alongside your business. When you invest in the Esko Kongsberg C Edge digital cutting table, you invest in your company’s future.

“Unlike other tables on the market, the C Edge is completely upgradable avoiding the impact of having to reinvest when a business expands. The C Edge evolves with your business to unlock production flexibility and profitability, and delivers exceptional cutting quality and milling accuracy at a remarkably cost-effective price.”

“With high speed production capability up to 75mpm, at an acceleration of 1G, the Kongsberg C Edge enables converters to produce high quality results with fast turnaround to meet today’s dynamic market needs.’

The C Edge handles a wide range of substrates used in the signage sector. He says, “you can fit the C Edge with the new second Fast Tool adapter to reduce manual tool changes and minimise downtime. When two Fast Tools are used together, you can achieve higher throughput with clever tool combinations and improve output quality, especially on signage materials like vinyls. The C Edge is also available with or without a conveyor.

For corrugated packaging manufacturers, the C Edge can also be fitted with a heavy duty unit with a 50kg downforce to produce high quality crease lines with a 150mm crease wheel. Blockley says, “Efficient and high-quality creasing, even at 100 per cent speed, is supported by CorruSpeed; a tool developed for cutting corrugated board at high production speeds without oscillation. The CorruSpeed tool delivers higher quality and generates significant time savings on a range of corrugated applications, even with recycled content.

“Esko has a proven track record of delivering speed, precision and production power through superior engineering and build quality. This next generation innovation fits well with this tradition.”

Learn more about the tabel and its complementary tools and software, or visit www.esko.com/en/products/kongsberg-cutting-tables/kongsberg-c-edge

The Esko Kongsberg table portfolio consists of two types of tables based on the type of work typically produced –choosing flexibility for versatile, creative jobs (Kongsberg X), or productivity for efficient production runs (Kongsberg C).