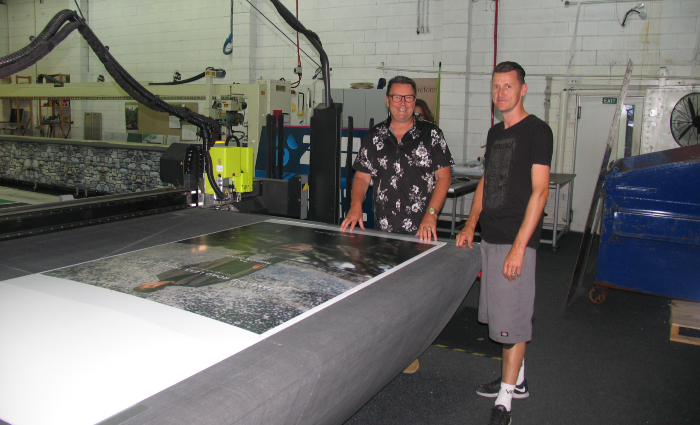

Premier wide format and digital print company Omnigraphics recently installed an Esko Kongsberg C cutting table through Fujifilm Business Innovation.

Steve Spear, managing director at Omnigraphics, says the cutting table fits well with the Omnigraphics operation. One of New Zealand’s largest wide format print companies, Omnigraphics, covers a massive amount of ground in wide format production. Its client base includes some of New Zealand’s largest companies and corporates, along with numerous small businesses operating in niche markets.

He says, “We are busy. We take on the largest possible range of jobs for large and small clients and we need a cutting table that can handle all we throw at it. This multi-function, super wide, digital finisher does that and more.

“The Kongsberg performs all the operations we ask it to do, from kiss cut to milling, and on a huge range of substrates, ACM, plywood – you name it.”

Omnigraphics is working towards becoming a PVC free shop. Spear says, “Sustainability has to be more than a buzzword and we are working to reduce our carbon footprint. The movement away from plastics to compostable substrates will continue and the Kongsberg cuts our sustainable substrates with ease.”

Angus Huisken, head digital operator at Omnigraphics, has a background in screen printing, sublimation and experience in nearly every aspect of wide format production. He says, “I am impressed with the Kongsberg. It handles everything we throw at it. For example, last week, we did some magnetic signs. Right now, it is cutting some foam board.

“It has a range of cutting tools and it will pretty much cut everything. The Kongsberg has an automatic tool adjusting system that uses camera inspection and digital image processing to adjust the tool in the machine at the start of each job. When we have a new job and we need a different tool, it sets up that tool for the selected substrate. So, changing over jobs is simple and so much faster than manually.

“One of its best features is the ease of operation. The software is simple to use. Like any machine, the Kongsberg has its nuances and you get used to handling it in a particular way.”

Grant Blockley, application and packaging specialist at Fujifilm Business Innovation, says “It is essential that your digital cutting table can handle the widest range of materials possible. Kongsberg cutting tables focus on removing non value added time from the production process and they place operational control and management tools into the hands of the operator.

“Esko Kongsberg offers a range of table sizes and configurations and the Kongsberg C table at Omnigraphics is the number one choice for short run production. It has set the standard for speed and acceleration, offering speeds up to 100 metres per minute, and acceleration up to 1.7G, together with ultra-fast tool movements. The cutter’s robust construction enables knife cutting of most materials at top speed.”

Omnigraphics has had a long relationship with Fujifilm Business Innovation. Spear says, “We leapt at the opportunity to purchase the Kongsberg and we get excellent support from Fujifilm Business Innovation. We also run other Fujifilm Business Innovation solutions such as the Versant 2100 digital production printer.

“We have always had the attitude that we want to take on any job for our clients, no matter how strange or difficult. The Kongsberg adds the kind of capability that allows us to say yes to our customers with confidence that we can continue to produce high quality work and on time.”

Blockley gives six reasons to own a Kongsberg C cutting table:

• Capability – The Kongsberg C is designed to handle all types of substrates, thick to thin.

• Capacity – The Kongsberg C offers a 3Kw continuous duty high-performance milling unit.

• Calibration – The Kongsberg C has a rack and pinion drive system, as opposed to a belt drive, to give outstanding accuracy anywhere on the table bed.

• Consistency – The Kongsberg C delivers the same performance every time, even on the most demanding materials or for the most complex jobs.

• Choice – The Kongsberg C offers size and productivity simultaneously, eliminating the need to own dedicated digital finishers for different applications.

• Complete – The Kongsberg C offers a full solution consisting of hardware, software, bits & blades, and services.