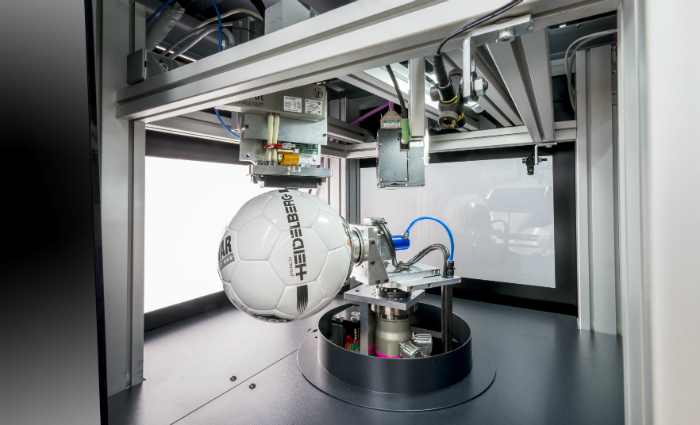

Heidelberg has presented its latest innovation in 4D inkjet printing with its Omnifire 1000 system, revealing what it describes as applications of the future.

Heidelberg wants printers to use its Omnifire1000 for direct printing on objects of different sizes, shapes and substrates such as helmets, suitcases and various sport apparel. It complements the Omnifire 250 range already on the market.

Jason Oliver, head of digital at Heidelberg, says,“What we are presenting is the customised future. Consumers today expect personalised, one-of-a-kind products. Manufacturers need an efficient and flexible industrial production process for this. That is precisely what 4D technology from Heidelberg offers with its Omnifire 250 and 1000 digital systems.”

Heidelberg selected German automotive supplier Ritzi Lackiertechnik as the pilot user for the Omnifire 1000 system, the business set to integrate the 4D application into its industrial production process to custom print both series parts and after-sales parts with a variety of coloured patterns. The introduction of Omnifire 1000 marks part of the group’s overall path to digitisation, according to the supplier.

Heidelberg implemented a digital strategy in 2013 under now retired CEO Gerold Linzbach that has resulted in the Primefire B1 sheetfed digital press, the Labelfire Gallus press, the Versafire rebadged Ricoh press, and now the Omnifire.