The country’s largest industrial fabric product manufacturer has a long history that goes back to its beginnings in 1937 as Sails & Covers, designing and producing sails and marine products.

During the 1970s, a company restructure saw the creation of Structurflex as a subsidiary of the sail-making business. The new company focused on the design and manufacture of industrial products, such as truck covers, marker buoys, railway wagon covers and flexible containers.

Structurflex has grown dramatically and developed new technology to become one of the world’s leading suppliers of innovative tensile membrane structures with a commitment to creating innovative, cost-effective products.

Simon Higgs, managing director at Structurflex, says, “We have manufactured truck curtains since the early nineties and for over 25 years, we outsourced the printing and signwriting.

Initially, a much larger portion of the curtains were signwritten, rather than printed, but as technology has improved, we have brought the graphics in-house.

“We still do some signwriting, but it is labour intensive, time consuming and there is a lot of waste with it. Also, it requires skilled staff, which are very hard to find these days.”

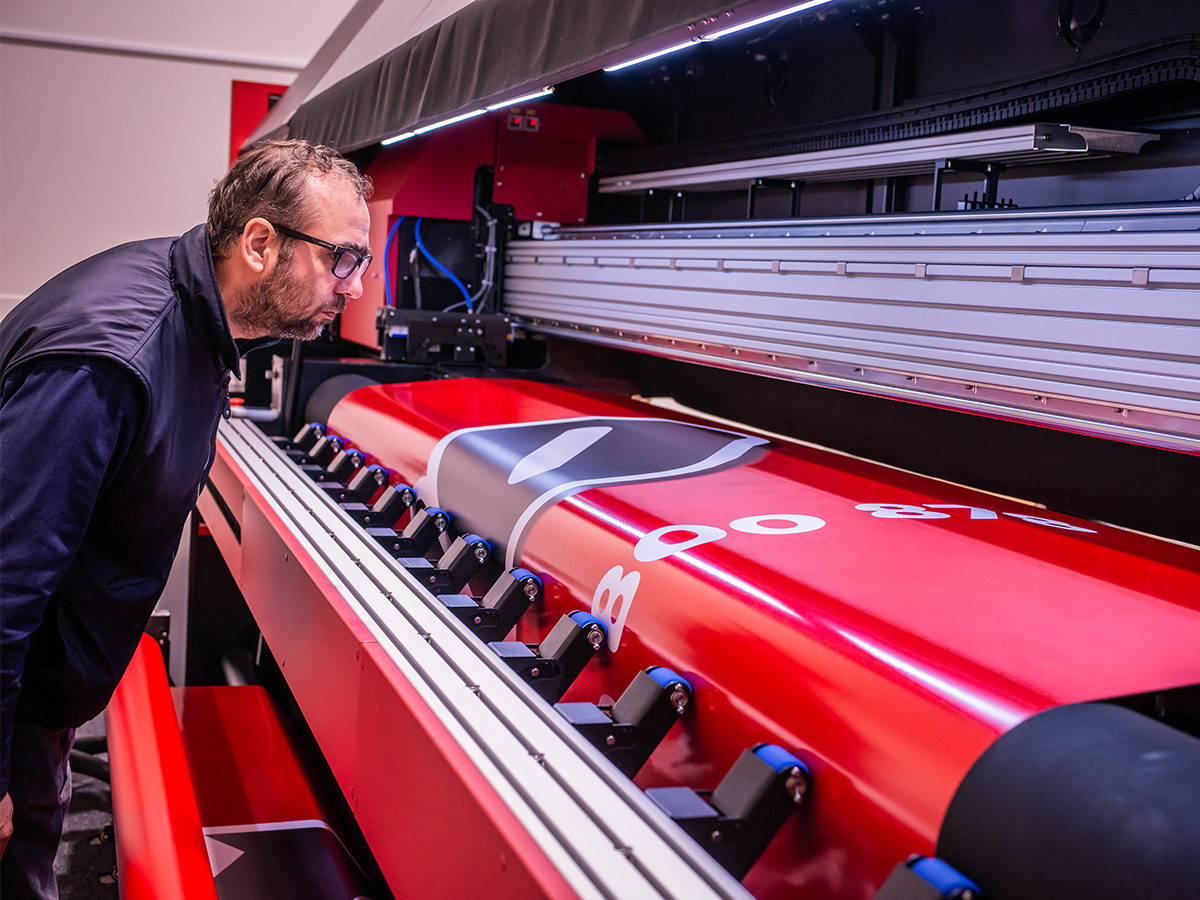

Last year, Structurflex installed an EFI VUTEk D3r, supplied and serviced through Currie Group. He says, “EFI has a proven track record in Australia and the two big curtain manufacturers there have this machine. We have a relationship with one of them, and I saw their machine in operation two years ago.

“Previous to installing this machine, we had not been in the printing business, so we were not looking to reinvent the wheel. We know printers in the past have failed on the truck curtain side of things because the requirements are different than other wide format printing. With a billboard, it does not open and close 50 times a day.”

The new printer has made a significant difference to production. He says, “When we used to outsource the printing, they could only print on white substrates. And, prior to getting the EFI, all coloured fabrics had to be signwritten. The EFI has given us the white ink, which enables us to print on the likes of yellow, green, blue, and black fabrics.

“The adhesion is amazing, better than we expected. The print quality could not be better. It is significantly better than the solvent printers used when we outsourced the work.

“We have cut down on transport and lead times. We now have the ability to do urgent jobs. For us, completing all the production in-house is the only answer as we grow. Our production bottleneck was always the signwriting, but the EFI has removed that.

“The EFI is printing on 900gsm truck curtain fabric and right now, we are printing three to four sets of truck curtains per day. We know it can handle more work, so we have capacity to grow. We use the EFI software, and it is pretty user friendly. The EFI VUTEk D3r is a reliable machine so we don’t have much downtime.

“As an option, we went for the super-duty winder, which helps when handling heavy rolls. This motorised winder uses a tensioning bar, reducing the chance of having a fault. We have the option to add other features, such as a slitter, in the future. We currently hang banners and truck curtains on the wall to clearcoat them, but the EFI has a clear option to print, which we are looking at using.”

Currie Group is impressed with how well Structurflex has integrated the EFI VUTEk D3r into its operation. Paul Whitehead, business unit manager, Sign & Display at Currie Group, says, “When installing this system, we knew the technology was proven. However, we went in knowing there would be a steep learning curve, given that in-house digital production was new for Structurflex. It has been amazing to see just how fast the team has got up to speed with the technology and more so, how much of the work has already now been converted to digital.”

Simon adds, “We have found Currie Group to be very helpful. We have a good relationship with Craig Paul, Currie Group New Zealand country manager, and Paul Whitehead in Australia is really knowledgeable. Currie Group’s New Zealand office is only a short drive from here, but we have not needed the technical support as much as we thought we would.

“We like providing our customers with high quality products and providing exceptional customer service and one of the cool things is that we see our products all the time.”