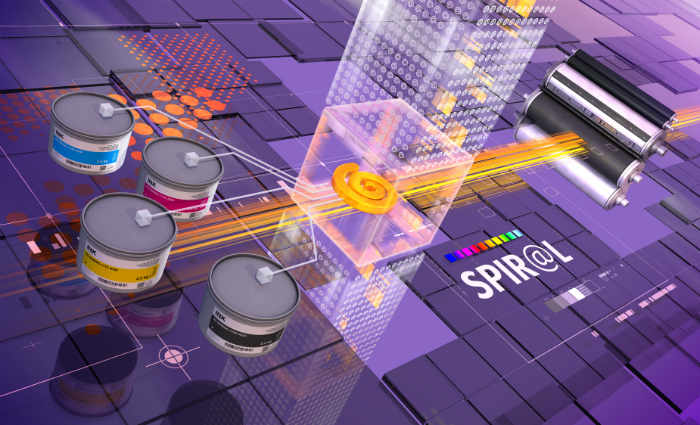

Agfa has launched SPIR@L, its latest patented screening technology that replaces traditional dots with alternative shapes.

The company says this the latest addition to its Eco³ programme increases quality and reduce production cost. The programme focuses on economy, ecology and extra convenience.

Erik Peeters, market manager for commercial print at Agfa, says, “The concept behind SPIR@L is simple but brilliant. We replaced the traditional dot used in printing with a more efficient spiral shape. That way, print jobs require less ink to fill in the exact same space, resulting in a crystal-clear image and a higher press efficiency every time.”

The patented screening technology has application in commercial and newspaper printing. Agfa says the process makes it possible to hold dots from press to paper ranging from one to 99 per cent without any additional effort, guaranteeing vibrant colours and sharp images.

The company explains that, due to the shape of the screen, print artifacts such as image slur or smaller CtP imaging artifacts become invisible. Agfa says that several early adopters confirm that this new screen avoids colour contamination in the blue colour range, yielding a higher quality reproduction. Due to the nature of the dot shape, the ink layer reduces, which positively impacts drying time or energy consumption.

SPIR@L requires no hardware additions to existing press and workflow setups.