Heidelberg subsidiary Gallus Group has unveiled its latest research breakthrough: Gallus MatteJet technology.

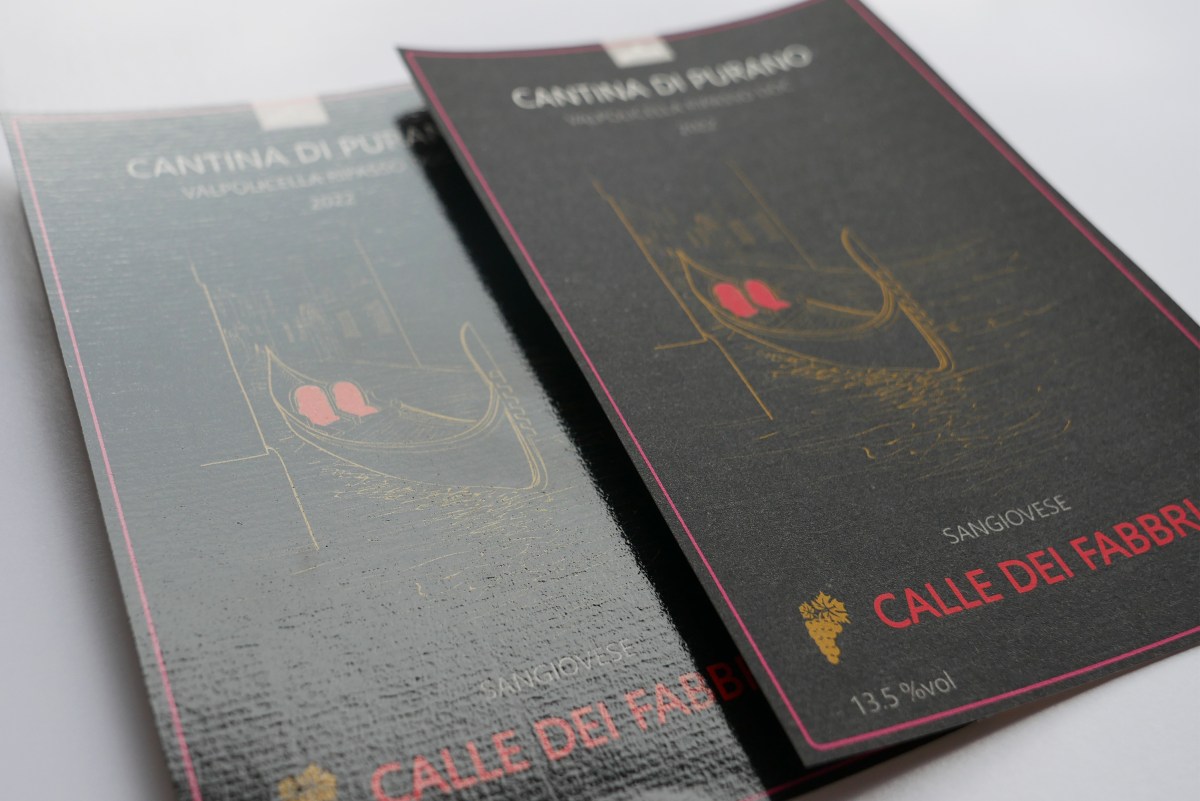

Announced at Labelexpo Americas 2024, Gallus says it represents an important advancement in inkjet printing, unlocking a premium matte finish previously unachievable with digital inkjet, bringing the possibilities of inkjet technology to the wine label market for the very first time.

Dario Urbinati, chief executive officer at Gallus Group, says, “The development of Gallus MatteJet technology marks a pivotal moment in the evolution of inkjet printing, opening up a world of new opportunities and ultimately, completely transforming the very foundation of what’s possible with inkjet technology.”

The company developed MatteJet in house at its innovation hub in St. Gallen. At Labelexpo Americas 2024, Gallus is exhibiting alongside Heidelberg, explaining how this innovation addresses one of the key challenges that, Gallus says, has historically restricted the growth of digital inkjet technology. Visitors are seeing how MatteJet will transform the entire market segment for wine and spirit labels and provide converters with the key to a profitable new area of business growth, according to Gallus.

New matte finish

The glossy finish inherent to digital inkjet technology has been one of the foremost barriers to its widespread adoption across labels and packaging, specifically in premium segments such as wine and spirit labels where brands traditionally expect a sophisticated matte finish, according to Gallus. It adds that, until MatteJet, this was only achievable through conventional printing, or the addition of post-processing equipment to use matt varnishes, adding time, complexity and cost.

The company says Gallus MatteJet technology delivers fast, cost-effective, and high-quality matte finishing capabilities, integrated directly into the digital inkjet process. This will allow converters, for the first time, to achieve a high-end matte finish at the touch of a button, without changing inks or adding overprint varnish, eliminating the need for external finishing processes or separate conventional machines.

Gallus adds that in removing one of the key barriers traditionally restricting the expansion of inkjet printing, its new process presents an opportunity for converters to now access a highly profitable market segment. MatteJet will also enable more converters and brands to enjoy the benefits of digital printing, such as more profitable short runs, personalisation, and on demand printing.

Urbinati adds, “By unlocking matte finishing for digital inkjet, we’ll be able to make an entirely new market segment accessible to converters without the sizeable investment into separate offset solutions – boosting profitability and exemplifying our commitment to building a new era of flexibility that will enable our industry to thrive long-term.”

System to Compose

Developed as part of the company’s ongoing research and development efforts at the Gallus Experience Centre, the new finishing process leverages advanced technology. Urbinati says, “We opened the Gallus Experience Centre with a vision for a dynamic, collaborative industry hub that would drive significant, meaningful industry change. Gallus MatteJet exemplifies this and is testament to the kinds of transformative developments that can be achieved when you combine this vision with real world insights as to what the market needs today, and of course the essential resources and expertise of our parent company, Heidelberg. MatteJet truly embodies our long-term mission and brings the smart, connected print future within touching distance.”

Designed to integrate with the Gallus Digital Printing Unit, the new MatteJet technology also represents further expansion of the company’s System to Compose concept, which provides compatibility across its leading product lines. Under the System to Compose, converters can add, adjust and remove units to their Gallus One as their business needs evolve. Gallus has expanded this to include workflow and service options as well as equipment.

At Labelexpo Americas 2024, Gallus says it is showing how the System to Compose concept empowers converters to pivot, adapt and thrive long term, with MatteJet now providing an additional piece to this puzzle.

In addition, the latest iteration of the Gallus One also made its global tradeshow debut, in the newly-expanded 430mm web width. Visitors to the stand saw its recently-extended colour gamut, with the integration of Orange and Violet Saphira inks developed jointly with Heidelberg.

Heidelberg is showcasing various aspects of its label offering alongside Gallus, having recently continued its expansion into new business areas.

Other label innovations include the latest developments in the Screeny screen printing solutions and Prinect workflow software. The companies add that Prinect, the backbone of System to Compose from Gallus, holds the key to digitising production and realising the smart, connected printshop of the future.