Across the Tasman, the University of Newcastle has begun setting up the first installation of its printed solar panels with global logistics solutions company Chep, a year after it made its debut with its 100 square metre demonstration site.

Professor Paul Dastoor, science and mathematics at the University of Newcastle says, “We have continued to develop the technology and we are currently setting up our first commercial instalment in the Hunter region. The rollout, delivery and installation process has started and we expect it to be finished by the middle of the year.”

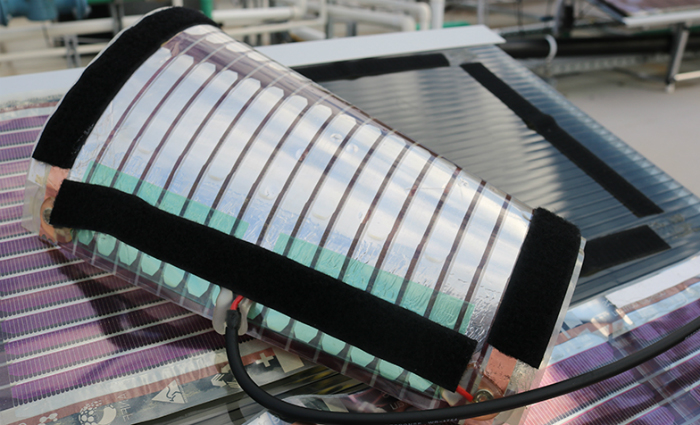

The university says the material will deliver a new functional printing revenue stream for the printing industry, with its production cost being less than $10 a square metre. The material is made by printing an electronic ink onto paper thin, clear laminated sheets using conventional presses.

Dastoor says, “The technology is an ink made with semi conducting materials. Most semi conductors in your phone and other devices are based in silicone. Using our technology we can use semi conductors and make electric circuits, and they are made to use solar power. We use straight forward printers, the same ones used to make wine labels. They are nothing special.

“We have been developing the technology for the last 20 years from small scale devices to large format up to our first demonstration project.

“On the back of five years of in-house development, all of the components of these advanced electronic inks are now synthesised at scale within our Centre for Organic Electronics using non-toxic carbon-based materials. These components are then used directly or further processed into water-based inks and paints.

“No other renewable energy solution can be manufactured as quickly. On our lab-scale printer we can easily produce hundreds of metres of material per day, on a commercial-scale printer this would increase to kilometres. If you had just ten of these printers operating around the clock we could print enough material to deliver power to 1000 homes per day.

“The low-cost and speed at which this technology can be deployed is exciting, particularly in the current Australian energy context where we need to find solutions, and quickly, to reduce demand on base-load power. We have had an enormous amount of interest from investors.

“It is a validation of the hard work of all of the people involved at the university, that people believe in the power of the technology. More than 20 years ago we were interested in solving global energy problems and the idea came about.”

A team from the University demonstarted the panels at Pacprint in Melbourne last year with a custom built pop up site.