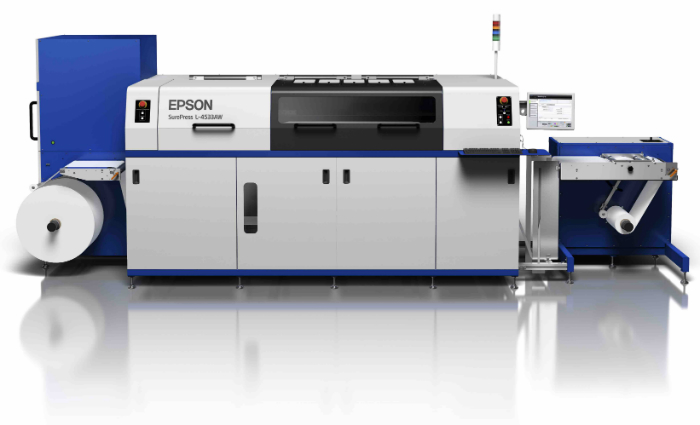

Epson has expanded its digital label press line-up with the introduction of the SurePress L-4533A, a six colour aqueous resin ink machine and SurePress L-4533AW, a six colour plus white aqueous resin ink press.

The company has aimed for high quality labels and packaging at a low total cost of ownership, along with easy operation and a build for a reliable performance, Epson has aimed the new presses at label converters and commercial printers.

Craig Heckenberg, general manager of the Business Division at Epson Australia, says, “Everyone appreciated the success of the SurePress L-4033 series so we wanted to build on that with new products to meet the growing label and flexible packaging market demand for shorter runs and faster turnaround times. The L-4533A/AW do just that.

“Boasting even higher print quality, greater operator productivity and improved media versatility, the new printers have more than 30 improvements over their predecessors. These improvements translate into users’ ability to print a wider range of applications, create more high value jobs and operate more cost efficiently.”

Epson says the new machines make short-run label printing with accurate colour reproduction on a wide variety of substrates easy. Both printers have undergone significant developments to meet the ongoing demand for fast turnaround, with longer automated printing times, email alerts and minimal maintenance.

The company has designed the presses to improve productivity and increase efficiency, providing advanced automated printing features that include up to eight hours of unattended printing, e-mail alerts and minimal manual cleaning. The company says the devices offer the highest levels of reliability with all components built by Epson including the ink, printhead, and controller, featuring versatile substrate support and print on off-the-shelf materials from 8cm up to 33cm wide and as thin as 0.08mm.

The presses have upgraded microprocessors, which the company says improves processing speeds up to 80 per cent compared to the outgoing models. Variable drop size starts at three picolitres and the presses offer a new larger ink drop size, ideal for large solid colour backgrounds found on packaging.

Epson says it has designed the new presses to print prime labels and flexible packaging efficiently and profitably. Additional features include Epson MicroPiezo inkjet technology; a wide colour gamut to deliver colour matching and gradients required for branded prime labels and packaging; and automated printing that enables a single operator to run multiple units at one time.

Supporting a range of substrates, the presses can print on off-the-shelf flexo PS label materials, including uncoated, gloss and semi-gloss papers, film and supported or unsupported media.

The machines also offer versatile data support as a solution for text, barcode, and image serialisation. The presses work with industrial-quality inks, with a seven-colour set consisting of durable, water-based, resin-coated pigment inks which Epson says give superior adhesion, produce a remarkable range of colours, and deliver water and abrasion resistance on most substrates.

Epson manufactures all the components, providing service, with training, workflow software and operational support included.