And long live printing that integrates alongside other communication channels. This is the way forward and, to get it right, you need to make two changes: throw away the old baggage you have carried for so long and embrace a change of mentality.

You must swap the old habits of traditional printing for digital ones.

Pierre Coquard, head of Industria, a Parisian print service provider with a passion for all things tailor made, and who sits on the verge of switching completely to digital printing, says, “I am optimistic for the years to come. There are fewer and fewer print experts within the customers we engage with. Our contacts are coming more often from higher up in their organisations, in marketing or communications, and they are facing broader challenges.

“They do not have a pure print problem but more a communications challenge. And those with a print problem alone often don’t know how to manage it.

“So, if a print service provider can offer relevant communication proposals, ensuring top quality within the required delivery schedule and with a positive communication result, then there is definitely business to be made.”

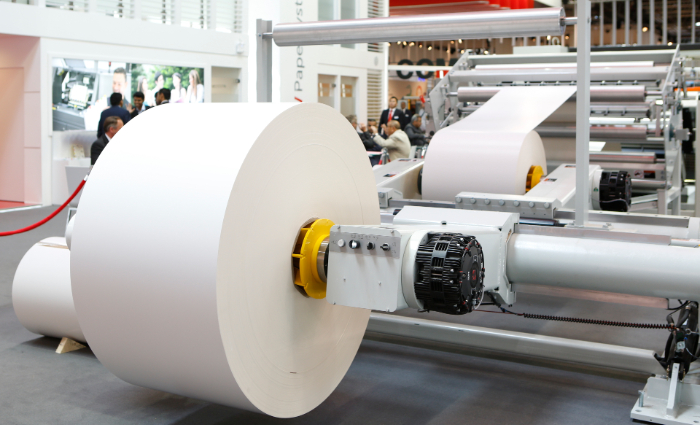

Printing has not changed as rapidly as it could have, as new technologies based on toner and inkjet have worked alongside the older ones (offset, rotogravure, screen printing and flexography). It certainly has benefited from all the advantages brought by IT and software, whether in traditional or digital printing and finishing equipment (small and large formats); in process management; or in marketing with multichannel or cross media communications.

We shouldn’t forget the numerous embellishments now available for all technologies and in all markets. In short, the print impression has been transformed, re-muscled, adapted and developed, while meeting a fundamental, necessary trend for reduced environmental impact (control of rejects, less waste, better inks, sustainable papers, etc.)

Some traditional printers, albeit too few of them, go ahead and develop full digital departments or replace offset presses with digital models. But that is not enough. Digital printing requires a change of mind towards flexibility of operation, responsiveness, different management schedules, and real tailor-made service.

It is no coincidence that major players in digital printing are often derived from smaller reprographic structures that already have a service culture.

A period of transformation

Today’s commercial printing industry is characterised by the rise of digital printing, including inkjet printing, combined with significant modernisation of traditional printing technologies.

Offset survives, thanks to technical advances: automation of calibration processes; reduction of waste; higher speed; 20,000 sheets per hour; offset-digital hybrid workflow; offset digital combinations in commercial, labels, packaging, and binding; with finishing equipment. Workflow developments are seen in all areas and internet printing (web to print) is booming.

It is now possible to respond to customer demands that could not have been met before, such as the printing of a single copy of a book; short print-runs for brochures or documents; as well as packaging and fully customised labels.

The demand for long-tail solutions can now be met with digital printing offers from a range of suppliers: Canon, Domino, Fujifilm, Fuji Xerox, Heidelberg, HP, Koenig & Bauer, Komori, Ricoh, Riso, Ryobi and so on.

The search for the best price is giving way to the search for the most profitable service for the customer.

Print only is being replaced by a universe with print in it; from order to delivery, without sacrificing creativity, quality and overall print profitability.

The key question becomes: ‘What is the return on investment of a print?’

Printed documents that can be de-materialised into the non-physical will continue to be de-materialised, so there is only one way to remain in business profitably: provide added value and related services.

Customers no longer want to be told how it works, but what it does in terms of results and impact. In this regard, print must contribute, that is, it must communicate effectively when integrated within a mix of media channels.

The return of print

Consumers are saturated with digital information.

However, they can be positively sensitive and receptive to different communications that engage them in a distinctive, personal way. These include invitations, brochures, books, photos, greeting cards, personalised documents using some of the advancements in 21st century print such as special colours (gold, silver and fluorescent), varnish, relief, new shapes, and form factors.

Coquard explains, “We see a return of print. A decade ago, it was cheesy, especially for young people. Now you have to know how to mix print with other modes of communication.

“We are rediscovering that well targeted print communication allows us to weave a link to customers.”

This is echoed in other industries where there is also a return to the physical such as Polaroid images in photographs and the vinyl album in music.

We are heading towards more automation of the print production process, from receiving the order, managing the files, to the shipping of the final print job. Customers want human proximity and fast turnaround time. These two requests are becoming more and more the key criteria for selecting service providers. But do you provide such capabilities when the client is miles away?

Equipment wise and, in order to deliver the latest services, more and more service providers are starting to use digital printing and embellishments systems. Examples of this include MGI and Konica Minolta; Scodix, and the Fuji Xerox Iridesse. In large format flatbed printing systems, we see associated cutting such as Elitron, Esko and Zünd.

The digital transformation includes small and large format. Signage, posters, point of sale, interior decoration, even textile or car wrapping are now fully digital.

Last but not least, environmental concerns are, for example, driving LED dryers to replace infrared dryers in all production printing systems. New substrates are changing the market landscape, enabling new applications and reducing environmental impact.

Online printing factories with offset printing fleets, small and large format digital printers will remain and will further grow, having conquered the various sectors of commodity printing. They will retain this, supported by customers, who are also print service providers, using them under the ‘white label’.

The consequence of all these recent developments: a new market segmentation is looming in printing.

We can distinguish six segments that sometimes overlap each other; similar to the food, home equipment, or business supply industries:

• Multi-service printing companies expecting customers to walk through the door anytime, often described as small convenient (corner) copy shops.

• Print providers located in metropolitan centres providing quality and fast turnaround time, serving key accounts to whom they have access and to whom they provide different print services.

• Print providers that are well equipped across multiple technologies, able to take on small and large orders. They have the necessary space being located on the outskirts of cities, however they suffer the disadvantage of depending on logistics and delivery times.

• The specialists (books, magazines, packaging, etc.) that have optimised production lines, printing and finishing or converting and have quite specific capabilities. They typically address national and international clients and markets.

• Printing factories, generally located near communication centres and airports that can efficiently handle commodity print jobs with optimised processes.

• Online printers, with fully integrated workflows across printing and finishing for efficient shipping and delivery across countries and borders. Users themselves need to upload the relevant content and select from among defined formats and substrates.

So the new mantra of the printing game is to define where you want to play and to do it right. The winners are the ones providing real services and addressing new segments and markets, moving away from commodity printing.

In the not so distant future, Amazon and Google, to name just two, are waiting on the weaknesses of today’s print players to then place their own pawns in the game, so as to expand their capabilities building on their proven networks and process expertise. Amazon has in fact already started this.

Journalist Raphael Ducos has observed the printing industry for decades, currently operating as a freelancer. One of the first journalists to advocate for digital at a time where digital had a reputation as the enemy of print, Ducos has continued to identify emerging industry trends. He predicted the consolidation of print companies and the emergence of on line printing. A masters degree in philosophy gives him a distinctive perspective on the industry.

New Zealanders wanting to attend drupa can book travel, accommodation and tickets through Robert Laing at Messe Reps, email robert@messereps.co.nz.